The Evolution E-Style Tubing Rotator

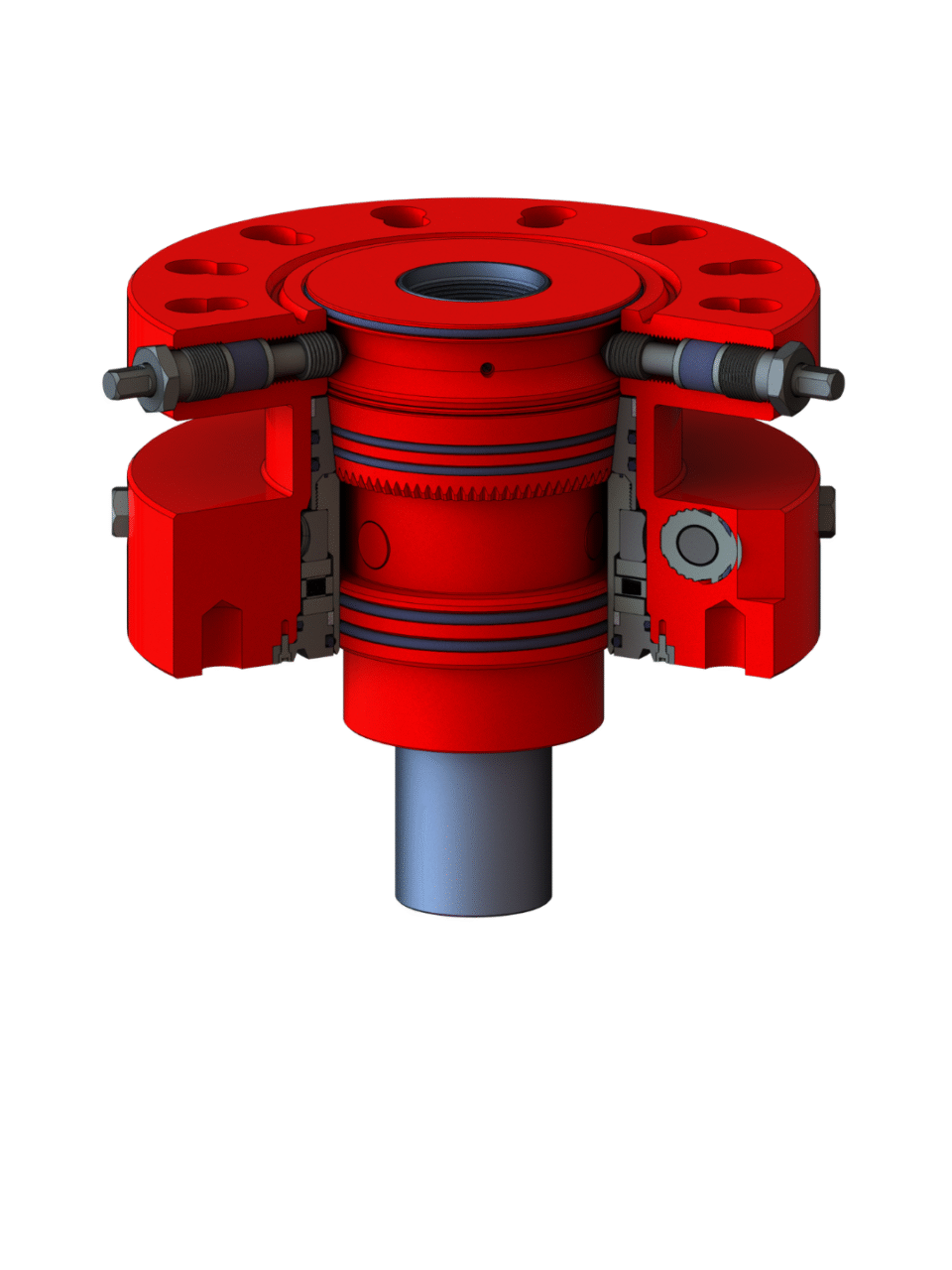

The Evolution Integral Tubing Rotator

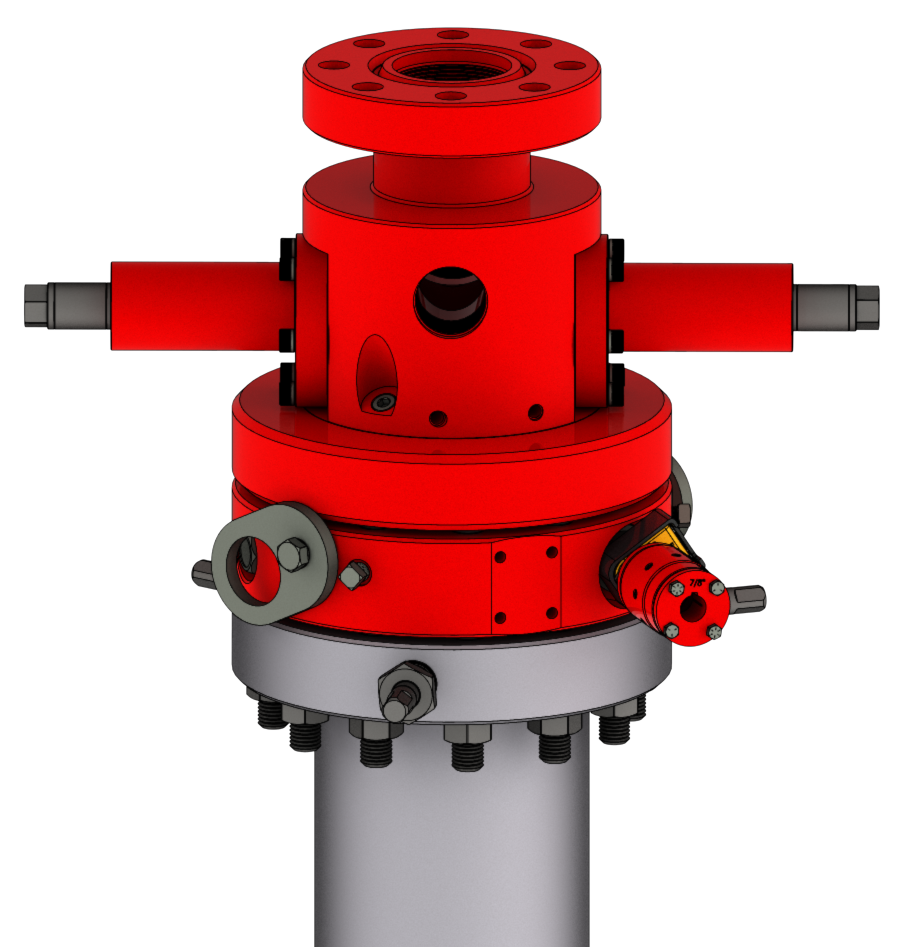

The Evolution E-Style Tubing Rotator

The Evolution E-Style Tubing Rotator (also known as the ‘Eliminator’) was developed as part of a system primarily designed to extend the life of production tubing in beam pumping and PC pumping wells.

Using a Tubing Rotator can extend the life of down-hole tubing by equalizing the tubing wear around the entire ID of the tubing instead of wearing through in a single spot.

Applications

- Bean Pump operations

- PC pumping wells

Key Features

- Minimal maintenance required

- Simple installation, removal, and maintenance

- Adds only 3.25″ to overall wellhead height

- Replaces the conventional hanger with rotating hanger

- Maintains well control while stripping blow-out preventers (B.O.P.’s)

- Able to re-grease while well is in operation

- Works in temperatures up to 410° F (200° C)

- Reduces sand build-up

- Prolongs tubing life

- Can be installed with a flush by unit

- Easy to service

- Counter available to track string rotation

The Evolution Integral Tubing Rotator

The Evolution Integral Tubing Rotator is designed to lengthen the life or tubing by slowly rotating the production string to prevent wear on a single point.

Key Features

- Can adapt to any profile of tubing head.

- Adds only 9″ (228.6mm) to wellhead height.

- Full bore in 7″ and 9″ (177.8 mm and 228.6 mm) configurations.

- Able to leave rotator on well during tubing intervention.

- Works with Evolution’s Auto Latch Hanger.

- Shear coupling prevents string over torque.

- Counter available to track string rotation.